Retail is detail

Every retailer has a large number of SKUs with differing seasonal sales patterns, physical sizes, profitability and roles in assortment. It is no easy task to optimise the performance of all the products in your supply chain to ensure that they deliver the best possible business results – perhaps best measured by overall profitability but also by a range of other indicators including market share and customer loyalty.

The inherent complexity of the task has been a major hurdle especially for mid-sized retailers wanting to bring in the latest, best-of-breed, supply chain planning tools. For a start any planning system needs to address the complexities of retail supply chains and these inevitably vary from business to business. It takes a lot of custom programming to get a regular planning solution to wrap tightly around the processes and business goals of any retailer or wholesaler. It’s a long and laborious process that makes it prohibitively expensive for the great majority of businesses.

Many of our mid-sized retailer customers have had successful results using the RELEX Business Rules Engine – a process automation tool – at a reasonable cost. This particular part of our supply chain management solution is designed to build business expertise and decision making into our demand forecasting and inventory optimisation, and to automate it. Our customers typically use the Engine to make sure that their processes are optimised towards achieving their business goals and to automate responses to recurring situations, such as the most common exceptions in the replenishment and forecasting processes. The Business Rules Engine lets companies design and build automatic monitoring for current and forecast supply chain KPIs and to set automatic responses for all perceived situations. Typically RELEX trains one or two members of the customer’s own team to take on the role of super-user. These team members then configure and adjust the business rules engine as needed. The tool is easy to modify via the UI so customers are able to automate their own working processes and business decision criteria wholly independently and without needing to call in consultants or refer back to RELEX.

Design and Build a Monitoring and Response System

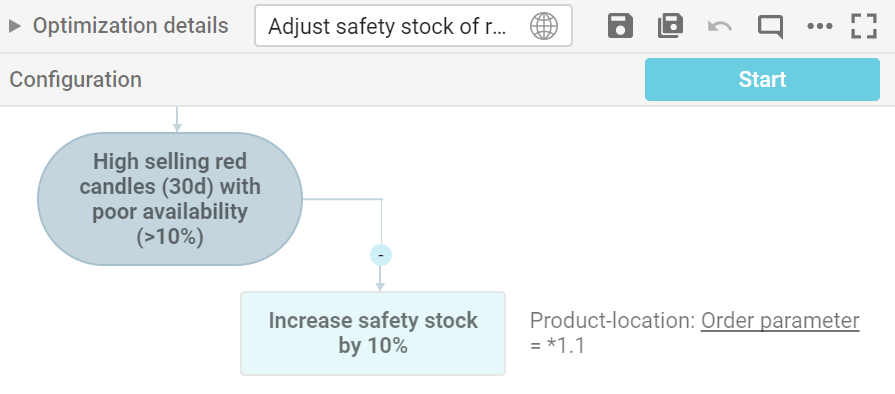

The Business Rules Engine essentially gives you two types of components from which you can design and build a monitoring and response system:

1. FILTERS (dark blue boxes in figure 1, below): These allow you to define which products require action (actions are displayed in light blue boxes below) to be taken. You first choose and edit the filter to define the group of stores/products etc. selected, then apply an action. This can either be built in during the design phase or added at any time.

For instance, as Figure 1. shows, you could build a rule that is specific to red candles that have sold more than 500 units during the last 30 days. Or you could create a rule for products that are likely to go out of stock within the next week and that have a lead time of under five days (or if the lead time is seven days for products that will run out within 10 days, and so on). Your only limitation is your imagination – the filters can use any master data or supply chain metrics you can think of.

2. ACTIONS (Light blue boxes in Figure 1.): These define what you want to do with regard to those ‘red candles’ or for those items at risk of going out of stock. You could adjust their safety stocks, delivery cycles or shelf displays. Furthermore, you can automatically set reference items for new products, allocate scarce or excess stock optimally or run an additional order.

Many of our customers find it quite hard getting their heads around the almost endless possibilities offered by our Business Rules Engine. It’s not surprising – It’s a tool that’s not available in any other enterprise software. We generally find that one of the best ways to illustrate how it works is by sharing a few examples of how various RELEX customers have used the engine. Then we provide users with a wide selection of the very best pre-generated rule-sets – filters and actions – that we’ve devised through years of experience in the field. Finally customers can add to those rules and actions ad infinitum to suit the unique needs of their own businesses.

Using the Business Rules Engine in practice

Next we will look at how we have used the Business Rules Engine to develop support for the following situations together with our customers:

- Automating the forecasting of new product introductions

- Automating optimal allocation of excess stock or allocation in stock shortage situations

- Effective automatic responses to supplier price changes

1. Automating the Forecasting of New Product Introductions

Case: Online retailer offering millions of products

Most retailers have to manage a lot of product introductions. The number of introductions at our customers ranges from a few hundred in grocery retail to over half a million at some larger department stores and general merchandise chains. Of course when you start looking to manage products at individual store level you effectively multiply one factor by the other (SKUs*outlets) – and the quantities of data you are processing grow exponentially.

Needless to say, the operating model where the merchandising team sets reference products for each product and/or allocates initial stock to the stores is both time consuming and prone to inaccuracy.

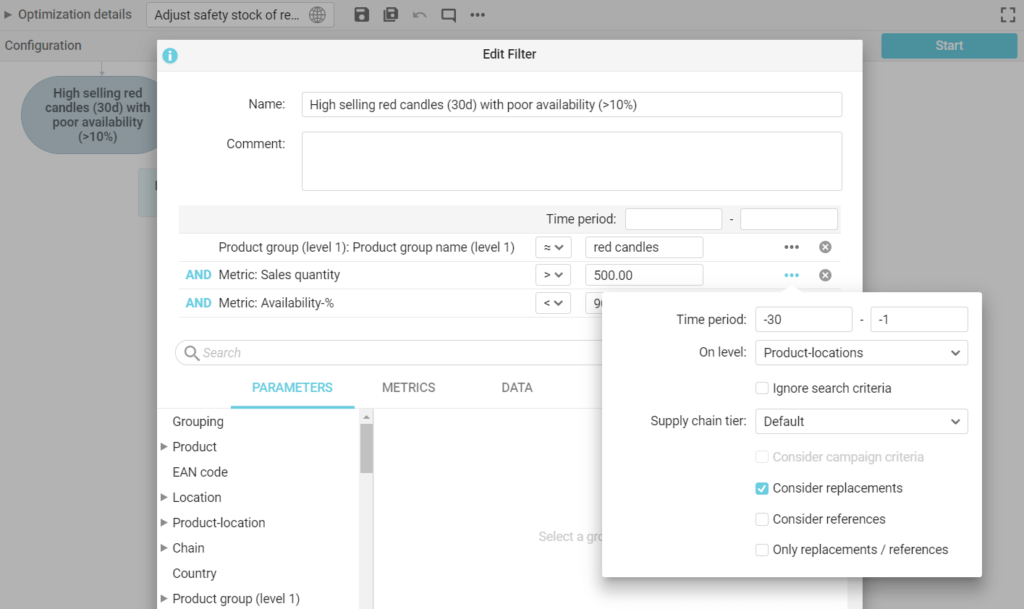

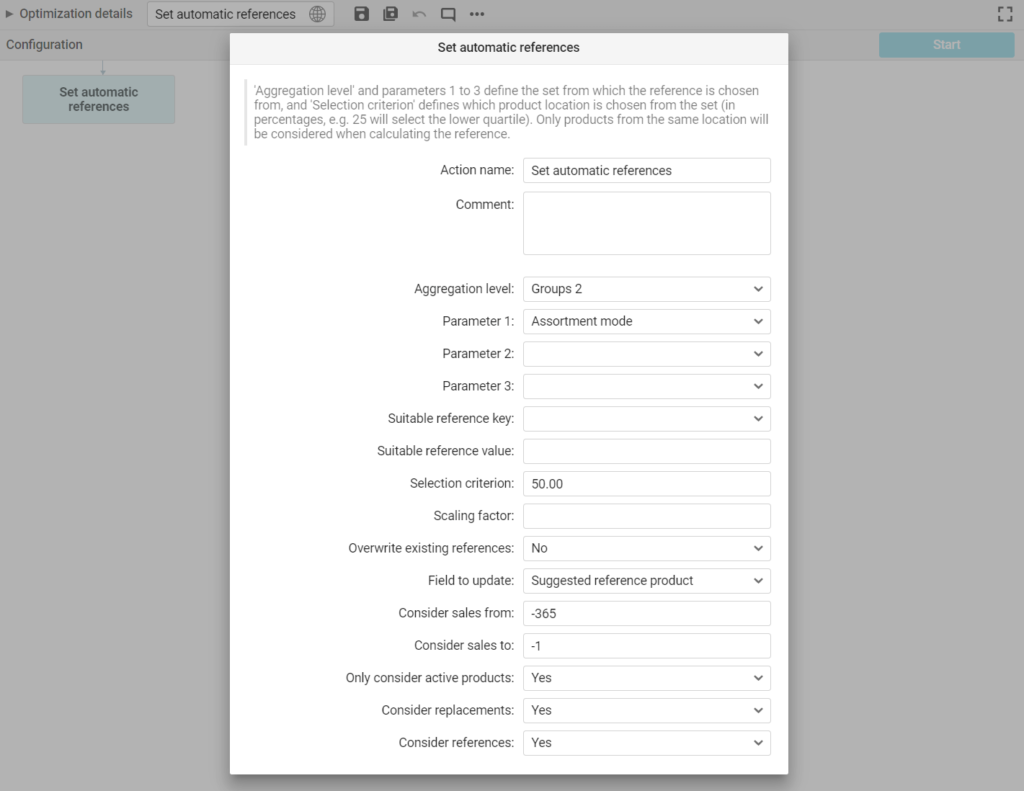

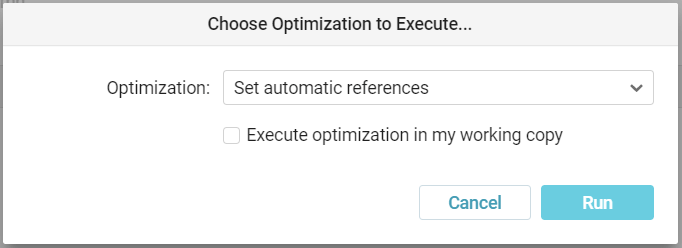

The starting point with automating new product introductions is to identify those products. For this, we would conduct a database search for products with an introduction date in the future, or if that option is not available, then simply by searching for any active products with no sales at all. This process of selecting and editing the reference products is shown in Figure 2. (below).

Next, we automatically assign reference products for each new product introduction we identify, for example, where a product is introduced that’s tagged ‘candle’, ‘red’ and ‘large’ the system might search for existing products with those tags. These reference products are then used to provide sample data, and are thus a reasonable basis from which to calculate a forecast for those products, that as yet, have no sales,– so the forecast would be based on the reference product’s sales history.

In practice different customers use different sets of criteria to map the best possible reference product for each new introduction. Most commonly the search starts by identifying the level in the product hierarchy where there are enough candidates for a reference product. Then the search is narrowed by further product data, quite often, for example, by price. Colours are also often used when searching for reference products.

If products have a distinct demand pattern at the beginning of their lifecycle then it is also possible to duplicate across the launch profile from the reference product, by using its launch-period sales figures.

Example

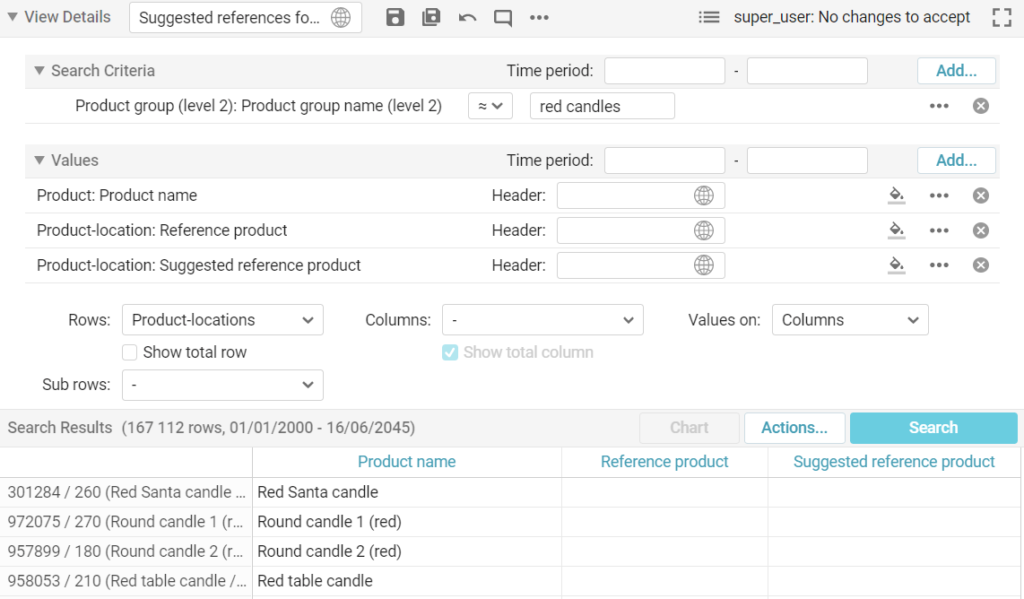

We have a customer that sells a lot of candles. During the implementation project we worked with the customer to build an automatic reference search in order to find reference products based on the previous year’s candle sales in the same price bracket. As Christmas was nearing we noticed that the process was flawed: red candles have totally different seasonal behaviour patterns than all other candles. So together with the customer we then modified the reference product search so that red candles sought a reference product from amongst existing red candle lines, while all other colours were referenced against their respective matches.

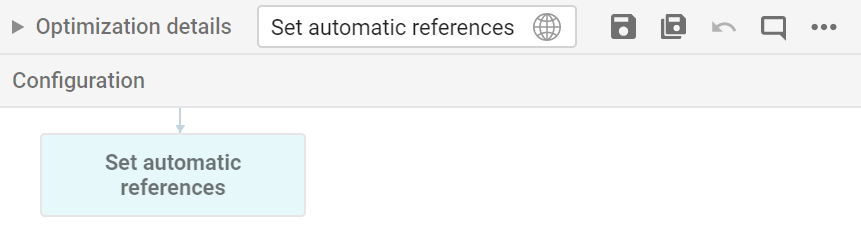

The process of setting the red candles as references is shown below in Figure 3.

2. Automating Optimal Allocation

Case: Excess stock or stock shortages at a food retailer

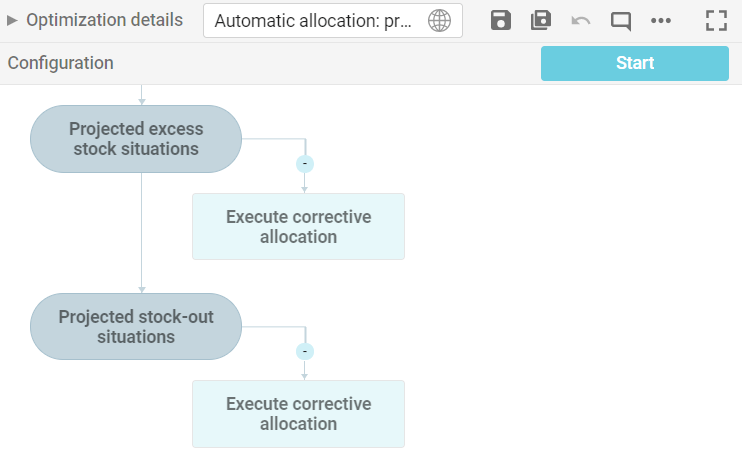

Many of our customers use our Business Rules Engine to monitor their future stock positions and to react automatically when necessary. In practice this means the system has been given parameters within which to act. Firstly replenishment teams can pre-define exceptional stock situations. The system will then monitor for these exceptions, issue an alert and then take action. This action will follow the lines defined in advance by users and could include (among other possibilities) allocation, reallocation and the issuing of purchase orders.

Example

One vertically integrated food retailer with a DC, and which produces a number of meat products, uses the Business Rules Engine’s tools to monitor future stock shortages, excess stock at its DC, and production capacity risks. The system automatically allocates stock to address upcoming situations before they become problems.

As a first step, the customer seeks to identify products that may raise stock level flags at the DC. They search both for excess stock and potential stock-out situations. This company’s response to both is similar. The search works by reviewing the forecast stock position at the DC one week ahead. If there is a risk of a stock shortage or of excess stock of short-shelf-life products, the stock is automatically allocated to its retail stores to minimise the impact.

The allocation of scarce or excess stock is done on the basis of the future demand forecast for each SKU in each store. Furthermore, the allocation takes into account both the current stock position and products already in transit to the stores so that stock levels reflect the bigger picture as well as possible.

3. Effective Automatic Responses to Supplier Price Changes

Case: Supplier price increases at a car parts wholesaler

Example

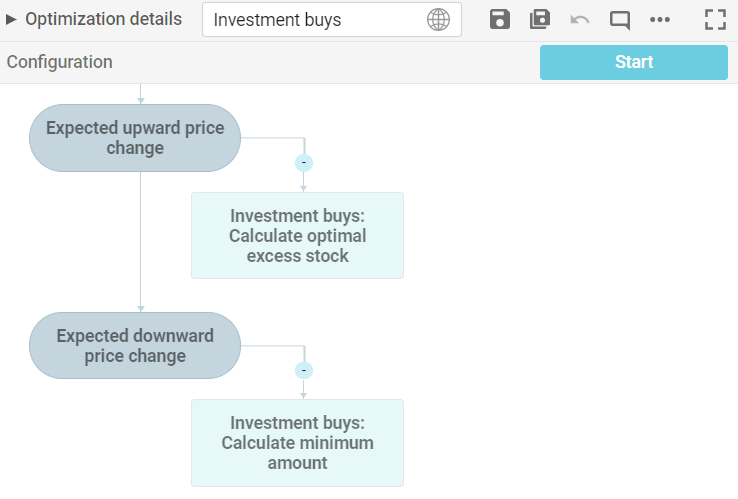

One customer, in the car parts sector, has configured its RELEX solution so that its purchasing responds automatically to supplier price changes. Those suppliers share their future price lists with our customer two to eight weeks before they come into force. The new prices, and the dates on which they become effective, are automatically read into the solution.

The customer has created a business rule that automatically monitors products with an impending price change. First, the solution assesses whether the price will go up or down. If the answer is ‘down’ the solution only buys the minimum amount needed to ensure stock availability until the price falls.

If the price is set to rise the solution works out how much excess stock it should buy in order to get the maximum economic benefit from the temporary price discount. This is done by calculating how much to buy so that the overall cost of purchasing and inventory carrying is as low as possible – the ‘optimal excess stock’ quantity.

The customer has also included two additional criteria to take account of practical constraints when ordering excess stock; budget and warehouse space.

The first ensures that any excess stock bought keeps within the purchasing budget set for each month. The second checks that there’s enough warehouse space to store the excess stock and can reduce the quantities bought to an appropriate level if storage space is tight. This process in RELEX user interface, is illustrated (below) in Figure 5.

By automating the process whereby price changes are monitored and purchase quantities are set to take account of practical constraints, the customer is reaping far greater economic benefit from price fluctuations.

Many of our customers make clear savings, quickly, by doing this.

Your imagination is your limit and common sense is your guide

These three examples are intended to give a sense of how a range of RELEX customers have put our Business Rules Engine to good and effective use. There are endless examples of exception situations that can be automated with it. The only practical limitation would seem to be the imagination of its users. However, and this is an important caveat, there’s no point implementing rules just for the sake of doing so. There needs to be a business rationale behind every rule. Each one needs to make you more efficient and more profitable or achieve a set strategic goal. There are plenty of rules that will. Don’t waste time on those that won’t!

Practical Advice for Working with Our Business Rules Engine

You need a vision

You need to know where you want to go. It’s a constant process.

- You’re in charge. You develop your controls and there are no limits. Nor are there external costs – everything can be done in-house. Nor are you limited to doing this just during the system’s design and implementation phase. Rather it’s a regular, ongoing process and one, with a RELEX system, that can be done quickly, in-house and without the need to bring in external agents with all the additional costs that can entail.

- To guide and keep this development under control, know what it is you are after.

- What are the most important goals in the process?

- What are the KPI targets and, even more importantly, which KPIs take priority?

Save only what works for you

Save only those parts of your existing processes that work for you and that make sense. You can easily create new ones where they don’t.

- Your old working practices may just reflect the constraints of your old tools and limitations

- At RELEX we encourage customers to re-evaluate and improve their processes constantly

Keep things simple

- Always try to make the controls as simple as possible

- Unnecessary complexity produces no gains but raises the risk of miscommunication within your user team.