Meat producers

Optimized supply planning, accurate demand forecasting

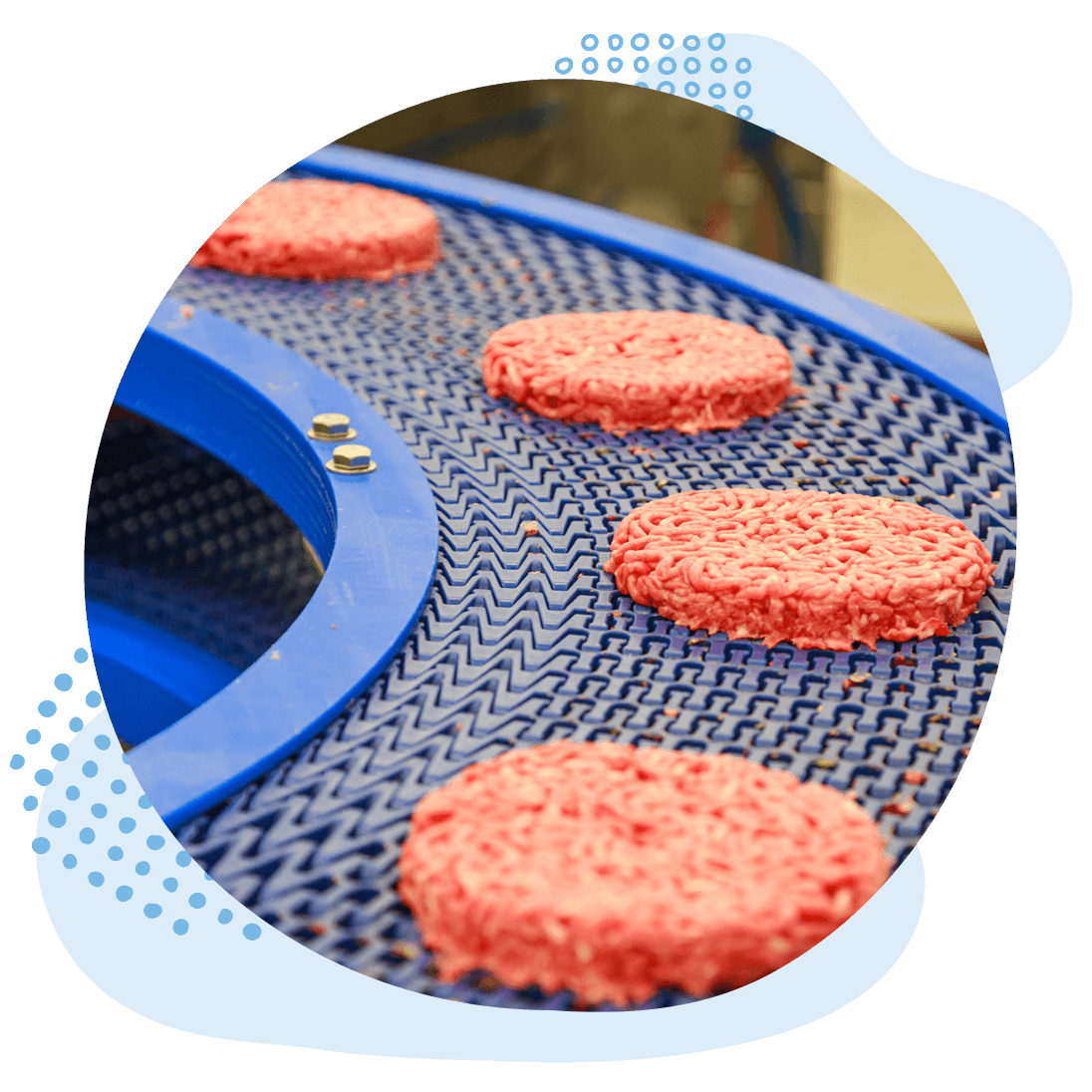

Meat processors face short order cycles, long supply lead times, seasonal variation and must maximize the yield of every animal while delivering the freshest products. Sharing data to align capacity, resources, and inventory with the sales plan requires visibility across the supply chain.

Address your biggest meat processing challenges

With long supply lead times and a lack of visibility throughout their supply chain, meat processing companies must determine how to best satisfy customer demand and maximize profit while also moving fresh products through the supply chain. Capturing fluctuating demand is important when collaborating with vendors and understanding how their promotions will impact supply and demand.

Need for accurate demand planning

Meat processors need to create day-to-day forecasts that accurately reflect business constraints. Failure to plan accurately risks losing sales due to poor product availability and incorrectly anticipated demand.

Outdated and siloed production planning

Outdated and disconnected manual planning processes in the purchasing, production, and distribution teams create constant gaps between planning and execution, resulting in less-than-optimal business outcomes.

Carcass balancing and yield

Carcass balancing is about matching demand with supply and making decisions regarding yield: which cuts to use, what can be downgraded, and which cut plans, out of thousands available, will deliver optimal profit and customer service. For purely fresh producers, minimizing what is frozen is key.

Balance supply with demand

Meat processors need to balance the supply of raw materials with demand that can change due to seasonal variations, promotions, and consumer preferences.

Inspiring customer stories

Optimize meat supply chain planning

RELEX allows meat processors to stay ahead of demand volatility and execute strategic short-term and long-term planning to meet demand, maximize yield and minimize waste. RELEX deconstructs silos to bridge the gap between planning and execution, while enabling strategic, cross-departmental decision-making.

Webinar recording: Optimizing meat & poultry supply chains

Watch the recording of our webinar to see a demo of end-to-end supply chain planning and optimization capabilities for meat and poultry producers. Hear from Ekro, a Dutch producer of high-quality veal products, and how they are optimizing production and planning with RELEX.

Resources you might be interested in

We’ve accumulated a wealth of supply chain & retail expertise from our 1,500+ planning specialists.

How demand sensing helps conquer FMCG supply chain chaos

This blog explores how forecasts built using demand sensing can result in fewer lost sales, reduced waste, and increased cost savings.

Transform consumer goods S&OP with next-level demand shaping

The blog discusses on how forecasts built using demand sensing can result in fewer lost sales, reduced waste, and increased cost savings.

Case study: Group of Butchers

Group of Butchers supplies high-quality, traditionally prepared meat products, ready meals, vegetarian products, and soups and salads to all major supermarkets in the Netherlands, Belgium, and Germany.

Ready to transform your supply chain & retail planning?

We’re happy to discuss your business needs and share how our market-leading, unified platform can help you drive profitable growth across your sales and distribution channels.