Wholesale margins run famously thin as companies attempt to strike favorable deals with suppliers while settling on appealingly low prices for customers. Throw in the added complication of selling seasonal and fresh goods, and wholesale grocers find themselves in an unenviable position. Any miscalculation in demand can result in costly spoilage or prohibitive holding costs — all while high inflation wreaks havoc on a wholesaler’s bottom line.

Grocery wholesalers have increasingly turned to smart supply chain planning platforms to boost these margins. The best planning solutions tackle inefficiencies both on the customer and supplier side to reduce operating costs without complicating wholesale supply chain processes.

Here are three key ways wholesale grocers should take advantage of a robust supply chain planning platform to fight supply chain pressures and raise wholesale margins:

1. Maximize wholesale margins with forward buying

Forward buying (also called investment buying) involves making a high-volume purchase of goods ahead of actual demand to take advantage of supplier pricing discounts. Imagine a supplier dropping the cost of a specific brand of potato chips by 20%. A savvy wholesaler could purchase three months’ worth of chips at this discounted rate instead of buying lower quantities of chips at the regular price week after week.

Promotions and discounts aren’t the only way wholesalers can leverage forward buying to their advantage. High inflation means cash held today is worth less tomorrow, so forward buying at a low price ahead of price inflation is another useful strategy to save wholesalers money.

Forward buying ultimately is a matter of risk versus reward, with companies reliant on manual processes effectively taking a gamble instead of making a calculated investment.

But forward buying is a tricky business, especially in the grocery sector. Many fresh products expire quickly, making them poor candidates for holding over longer periods. Wholesalers caught carrying even excess ambient products for too long find that holding costs erase the initial price advantage.

Forward buying is ultimately a matter of risk versus reward, with wholesalers reliant on manual processes effectively taking a gamble instead of making a calculated investment. Companies must identify the break-even point between risk and reward regarding how much of a product to buy on discount. They must also project for future ordering needs to better align these predictions with forward-buying opportunities.

Fortunately for wholesalers, technology has made the practice much easier. An AI-powered planning platform automatically forecasts demand and calculates optimal rates with speed and accuracy that an entire team of human workers couldn’t replicate. A planning platform runs these tasks in the background, allowing wholesalers to instead allocate their workforce toward value-adding tasks a machine can’t do. Truly robust platforms can even be fed the data necessary to make considerations for different accounts, space assignments, and spoilage.

2. Minimize food waste with batch-specific spoilage projections

Grocery wholesalers manage a wide assortment of fresh and ambient goods with widely varying expiration dates, making food spoilage a continuing cost concern. Now recent demand volatility has compounded the issue. Sudden demand shifts may leave wholesalers with numerous shipments of the same product. And businesses making forward buys must always keep an eye on which shipments arrived first to ensure first in, first out (FIFO) inventory management and avoid food waste.

Different batches of the same product may also carry different expiration dates depending on factors like production issues and delivery delays. Complexity compounds when wholesalers have different minimum shelf lives for the various customers they supply. A premium grocer may demand a six-month shelf life for a product, while a discount chain happily accepts three months.

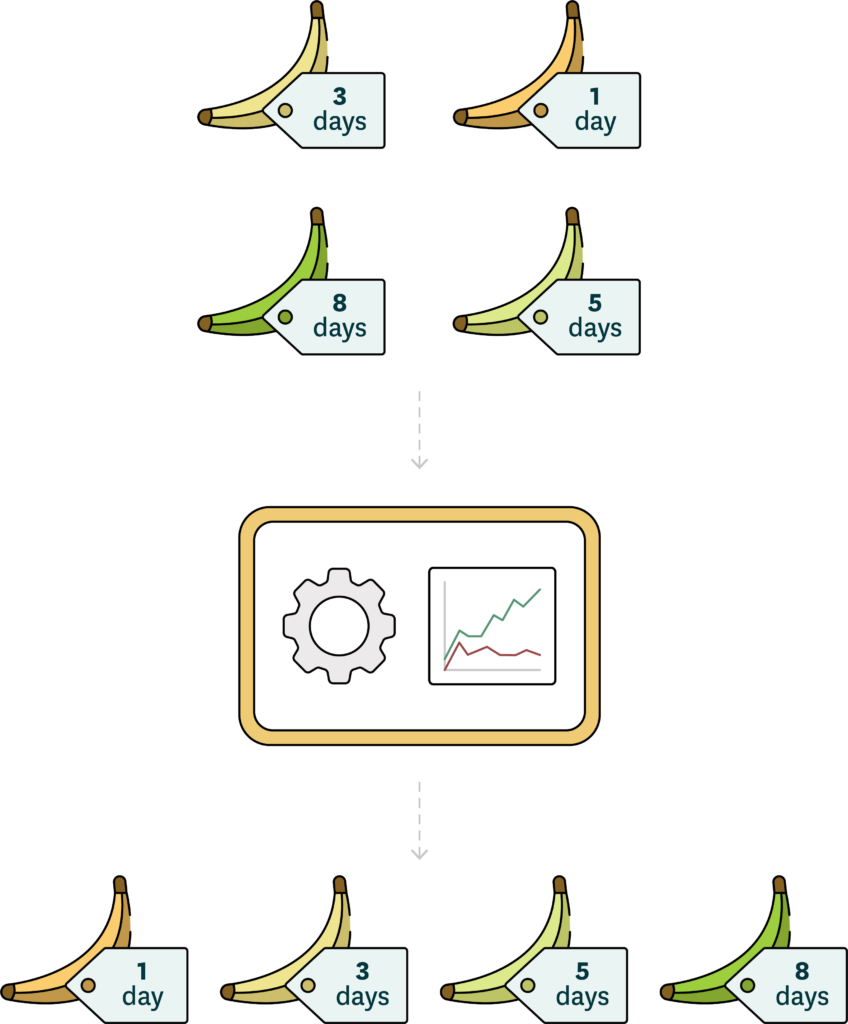

To illustrate this issue, consider a wholesale grocer that receives three batches of bananas in a single week:

- Batch 1 arrives Monday and expires next week Tuesday.

- Batch 2 arrives Tuesday but expires this coming Friday.

- Batch 3 arrives Wednesday and expires next week Monday.

Manual processes can’t keep track of when specific batches of a product expire in a warehouse that carries thousands of products. Wholesalers also face workforce shortages that only worsen the limitations of manual systems. And most in-house digital planning tools aren’t capable of keeping track of batch-specific spoilage.

Yet batch-specific spoilage projections are possible with select smart planning platforms. This capability allows wholesale grocers to identify when certain batches spoil within the same product category, reducing food waste and its associated costs. It’s an essential feature for any business looking to put out their soonest-to-expire products ahead of others regardless of when the products roll in.

3. Improve forecast accuracy using channel-specific forecasting

Most wholesale grocers don’t take full advantage of their digital demand forecasting capabilities. Companies often overly focus on what volume of products are shipping out instead of where these products are going. A more granular look at product destination would reveal new places to optimize efficiency and thus boost wholesale margins.

Channel-specific forecasting (or simply channel forecasting) is the practice of clustering similar customer accounts together and creating specific forecasts for each unique segment. Channel forecasts allow companies to better understand the unique behaviors and needs of their customers. Supermarket customers and C-stores each behave differently, so forecasting separately for each increases the likelihood of the right inventory being in the right place at the right time.

Separate channels could be created for customers who:

- Share a similar physical location, like restaurants situated within or near a major resort

- Share similar seasonality, like convenience stores near college campuses

- Have unique guidelines, restrictions, or assortments

- Command exceptionally high volume

The best planning platforms also forecast by sales and fulfillment channels to further increase forecasting accuracy and internal alignment. Any wholesaler facilitating online sales likely saw a temporary but substantial dip in demand from brick-and-mortar customers while seeing a massive spike in online ordering. It would be more efficient to split these channels and forecast demand separately for each instead of lumping them together.

Companies often look at the big picture — but a more granular look would reveal new places to optimize efficiency.

Wholesale grocers also face stiff penalties for falling short of on-time-in-full (OTIF) guidelines set by companies like Amazon and Wal-Mart. The creation of separate channels for these priority customers ensures that necessary inventory is allocated for them first to avoid these costly fines.

Use RELEX to optimize supply chain planning and boost wholesale margins

Grocery wholesalers might find it difficult to justify investing in new technology as their margins erode due to inflation, shortages, and other supply chain woes. But the increased volatility of the supply chain potentially makes sticking with inefficient existing solutions more costly than investing in a better one.

RELEX grants wholesale grocers greater visibility into the entire supply chain, allowing companies to make smarter forward buys without risking overstocking. Wholesalers worldwide have used RELEX to greatly improve forecast accuracy to decrease food waste while providing high levels of service to their retail customers. RELEX automation and machine learning capabilities are market-proof, helping wholesalers maximize profitability in favorable and unfavorable markets alike.

Raising wholesale margins through supply chain optimization requires a myriad of digital features and capabilities — but, luckily, only one solution.